A Complete Paper Guide

(For Designers, Marketers & Buyers)

Choosing paper isn’t just about “thick vs thin.” The sheet you pick controls color vibrancy, tactile feel, durability, cost—and ultimately how your brand is perceived. This guide explains paper types, finishes, thickness, and best‑fit use cases so you can brief projects confidently and avoid costly reprints.

How to Choose (Fast 3‑Step Framework)

Brand Feel: Minimal & natural → uncoated. Premium & glossy → gloss UV/laminate. Modern & understated → silk/matte. Eco/raw → kraft/recycled.

Use & Durability: Heavy handling (menus, cards) → higher GSM + laminate/UV. Short‑term (flyers) → lighter GSM coated. Writable (forms) → uncoated.

Production & Budget: Small runs → digital‑friendly stocks (coated or uncoated). Special finishes (foil/emboss) → sturdier cover boards.

Tip: Ask for a dummy (blank mock‑up) in the intended GSM to judge stiffness, fold, and mailing weight before you print.

Paper Metrics—What They Really Mean

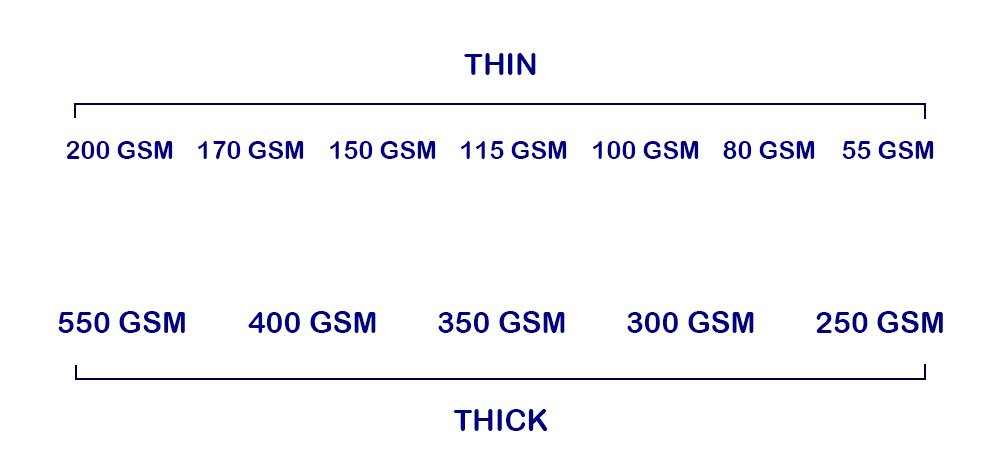

GSM (g/m²): Weight per square meter. Correlates with thickness but is not the same.

Caliper / Micron (µm) or Point (pt): Actual thickness. Higher = thicker.

Bulk/Stiffness: Some papers feel stiffer at the same GSM (important for cards).

Opacity: Resistance to show‑through—key for double‑sided text.

Brightness/Whiteness (CIE): Affects contrast and color accuracy.

Shade: Cool white (blueish), neutral, or warm (cream). Impacts skin tones and brand colors.

Grain Direction: Impacts folding and cracking; fold with the grain when possible.

Core Paper Categories

1) Uncoated (Offset/Bond)

Natural, non‑glossy surface with gentle ink absorption. Best for text‑heavy pieces, stationery, forms, certificates. Pros: Writable, low glare, tactile. Cons: Colors print softer; photos look muted vs coated.

Typical uses: Letterheads (90–120gsm), envelopes (100–120gsm), notepads (80–100gsm), books/journals (80–120gsm).

2) Coated Art Papers

Factory‑applied coating yields smoother surfaces and higher color density.

Gloss: Maximum shine & punchy color. Fingerprints/glare possible. Hard to write.

Silk/Matte: Subtle sheen, excellent readability, refined look. Some pens write okay; still less writable than uncoated.

Typical uses: Flyers & brochures (130–170gsm), posters (170–200gsm), magazine covers (200–300gsm).

3) Textured & Specialty Papers

Linen, laid, felt, hammered, cotton, pearlescent, metallic, black‑dyed, translucent vellum. Best for high‑touch brand pieces (invites, premium cards). Check finish compatibility for foil/letterpress and plan higher GSM for deboss.

4) Kraft & Recycled

Brown kraft and high‑recycled whites for eco‑led brands. Pros: Natural look, strong tear resistance (kraft). Note: Colors shift warmer on brown stocks; use high‑contrast inks or white underprint.

5) Synthetic & Label Films

PP/PET/PVC “papers” (e.g., Yupo) and adhesive label stocks. Pros: Tearproof, water/oil resistant. Best for outdoor tags, durable menus, product labels. Measured in microns for films; labels include facestock + adhesive + liner.

6) Packaging Boards & Corrugated

SBS (Solid Bleached Sulfate): Premium white board for cosmetics, pharma.

FBB (Folding Box Board): Lightweight, stiff, widely used for retail cartons.

Duplex/CCNB (Greyback): Cost‑efficient; white front/grey back.

Kraft Back/Clay Coated Kraft: Strong, natural aesthetic.

Corrugated (E/B/C flute): Shipping/display strength; print via litho‑lam, digital, or flexo.

Finishes, Coatings & Enhancements

Aqueous (AQ) Varnish: Inline, eco‑friendly, quick‑dry protective coat (gloss/satin/matte). Budget‑friendly scuff resistance.

UV Coating (Overall or Spot): High‑gloss, hard‑wearing, chemical/scratch‑resistant. Requires coated surface; works best on cover weights (≥200gsm). Not ideal on uncoated.

Lamination (BOPP/PET): Gloss, matte, or soft‑touch. Improves rigidity and durability; ideal for menus, cards, packaging. Soft‑touch gives a premium velvety feel but scuffs if mishandled—consider anti‑scratch film for longevity.

Foil (Hot/Cold), Emboss/Deboss, Letterpress: Add tactile luxury; pair with heavier boards and mindful layouts.

Spot Effects: Spot UV, raised UV/foil create contrast on matte/soft‑touch bases.

Writeability: Uncoated = best. Matte/silk (no laminate) = moderate. Gloss/UV/laminated = poor (use permanent markers).

Recommended GSM by Product (Quick Reference)

| Product | Everyday | Premium | Notes |

|---|---|---|---|

| Letterhead | 90–100gsm uncoated | 120gsm cotton/uncoated | Laser/inkjet compatible |

| Envelopes | 100–120gsm | 120–140gsm | Match letterhead shade |

| Flyers | 130–150gsm gloss/silk | 170–200gsm silk + AQ | For heavy ink, go ≥150gsm |

| Brochures (inner) | 130–170gsm silk | 170–200gsm silk | Image‑heavy content |

| Brochure/Catalog Cover | 200–250gsm | 300gsm + matte lam | Add crease score at folds |

| Posters | 170–200gsm | 200–250gsm | Outdoor: consider synthetic |

| Business Cards | 300–350gsm | 400–600gsm + soft‑touch | Duplex/triplex = ultra‑premium |

| Postcards | 300–350gsm | 400gsm + gloss UV front | Postal handling needs stiffness |

| Menus (Reusable) | 300–350gsm + lam | 400gsm + soft‑touch/anti‑scratch | Wipe‑clean protection |

| Presentation Folders | 300–350gsm | 400gsm + matte lam | Add capacity spine if needed |

| Hang Tags | 350–400gsm | 500–600gsm kraft/cotton | Drill hole reinforcement |

| Packaging Cartons | 250–350gsm FBB/SBS | 350–450gsm + laminate | Product weight dictates board |

| Labels | 70–100µm PP film / coated paper | Durable film + varnish/lam | Consider adhesive (permanent/freezer/removable) |

Finish Selector—By Goal

Maximum Color Pop: Gloss art paper + overall UV or gloss lam.

Premium Minimal Look: Silk/matte art + soft‑touch lam + spot UV or foil.

Natural & Writable: Uncoated (offset/bond/cotton).

Eco Aesthetic: Kraft or recycled white; use bold, high‑contrast design.

Outdoor/Heavy Use: Synthetic film or laminated boards; anti‑scratch where needed.

Common Mistakes (And Easy Fixes)

Assuming GSM = Thickness: Check caliper and stiffness, not just weight.

Cracked Folds on Dark Covers: Add lamination + crease with grain.

Smudged Signatures: Avoid UV/laminate where you need to write; keep a writable panel.

Dull Photos on Uncoated: Move to silk/gloss or apply a protective AQ.

Menus Ruined by Spills: Always laminate or use synthetic for wipeability.

Sticker Confusion: Paper GSM isn’t the full story—labels = facestock + adhesive + liner; use films (PP/PVC) for water/oil resistance.

Dubai/UAE Practical Notes

Humidity & Handling: Lamination or UV helps menus, cards, and cartons resist scuffs in high‑traffic venues.

Outdoor Heat: Use synthetic films and UV‑stable inks for signage/labels exposed to sun.

Sustainability: Ask for FSC/PEFC options or recycled content where brand values require it.

Quick Brief Template (Copy/Paste)

Objective & brand feel:

Item & size:

Quantity & print method (if known):

Paper (type + GSM) preference:

Finish (AQ/UV/lamination/foil/emboss):

Writable area needed? Y/N

Folding/creasing/die‑cuts:

Durability (light/medium/heavy handling):

Sustainability (FSC/recycled):

Deadline & budget range:

FAQs

Q1. Is matte “just less shiny gloss”?

No. Silk/matte coated stocks have a smoother, low‑sheen surface that reads elegantly and reduces glare. They print sharper than uncoated but feel more premium than high‑gloss.

Q2. Can I write on matte or UV?

You can write (with some pens) on matte/silk without laminate/UV, but uncoated is best. UV, gloss lam, and soft‑touch resist most inks.

Q3. Does higher GSM always look better?

Heavier isn’t always better. Choose GSM based on handling, postal weight, and finish requirements. A stiff 350gsm can feel more premium than a bulky but soft 400gsm.

Q4. Why do my dark covers crack at the fold?

Coated inks and heavy coverage crack when folded dry. Add lamination and crease with the grain.

Q5. What’s the right stock for retail cartons?

Start with 300–400gsm FBB or SBS; add matte/soft‑touch lam for premium touch and scuff resistance. Heavier or fragile products may need corrugated inserts.

Need Help Deciding?

Share your project goals and we’ll recommend stock, GSM, and finish that balance look, durability, and budget—plus provide press‑ready dielines and mock‑ups on request.

You must be logged in to post a comment.